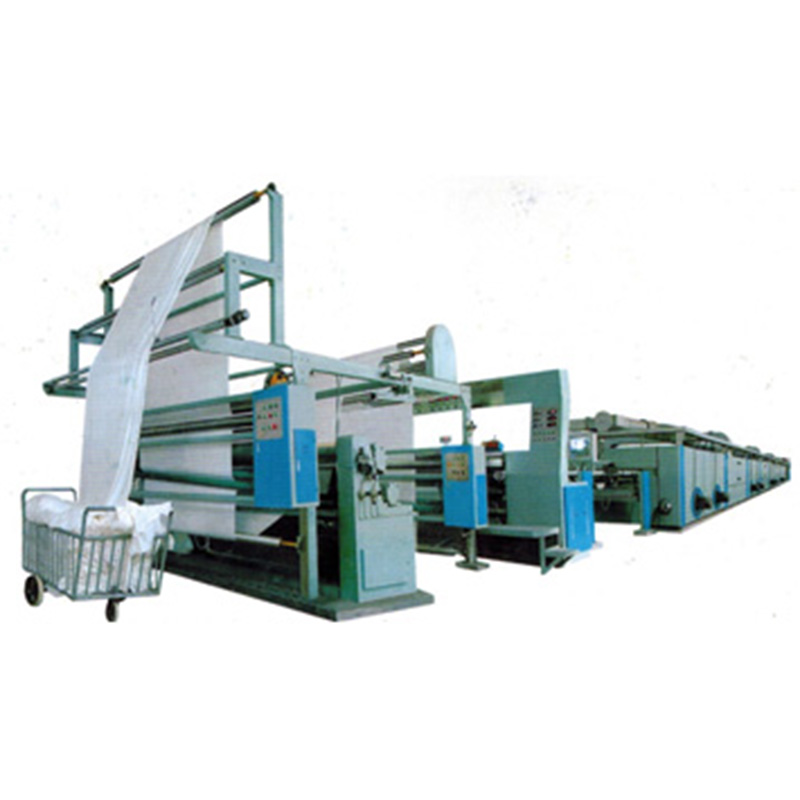

QDYL2600 Stentering setting machine

Saklaw ng paggamit ng produkto

Naaangkop ang produkto sa sutla, koton, lana, linen, paghabi ng kemikal, pagniniting na ahente ng dip pad, pag-inat, pagpapatuyo, paghubog.

Teknikal na parameter

anyo: sirkulasyon ng mainit na hangin. Single-layer

pahalang: sub-kaliwa at kanang uri.

Nominal na lapad (mm): 2200. 2400. 2600. 2800. 3000 ·

saklaw ng pagsasaayos (mm)700-2000; 700-2200:700-2400,700-2600; 700-2800 ·

NOMINAL NA BILIS: 60m/min (saklaw ng bilis: 5-60m/min) ·

overfeed rate: lo%-}30% (nominal speed: 60rn/min, overfeed rate hanggang + 90%) ·

Temperatura ng Oven: 100-220 ° C

Pinagmumulan ng init: mainit na langis, gas/coal gas, singaw ·

anyo ng paghawak ng tela: pin-clip, cloth-clip, double-use pin-clip

drop-cloth form: Pendulum o pendulum, double-use roll-cloth

Edge detection: high-precision Infrared probe-

Gabay: oil-lubricated cast-iron guide-rail

haba ng oven: 4-10 seksyon, bawat isa ay 3m

Proseso

horizontal feed → thread expansion → infrared alignment → down-overfeed → mechanical weft-straightening → thread expansion upper overfeed → stripping needle o upper clip (slurry edge)→ stretching o heat setting → cold air cooling → trimming, suction → needle-off o clip-cold water roller cooling (hindi ginagamit para sa pagniniting)→ Pendulum Drop o roll